Polymers

A polymer is a substance or material made up of macromolecules, which are very big molecules made up of several repeating subunits. Both synthetic and natural polymers play significant and pervasive roles in daily life as a result of their wide range of features.

GP10001

Antioxidant blend for polymers, non-blooming, FDA-listed, non-staining.

options

From $25 /lb

AK100

Versatile, high-performance silicone oil for industrial lubrication and release.

options

From $65 /gal

GUMARAB

Natural stabilizer and thickener used in food, printing, paint production, and more.

options

From $16 /lb

BROSIN

Light yellow-amber rosin flakes from Pinus Elliottii for versatile uses.

options

From $3.45 /lb

MCC101NF

Purified cellulose excipient for direct compression and granulation.

options

From $5.36 /lb

MCC102NF

Purified cellulose excipient for pharmaceutical binding and filling.

options

From $5.36 /lb

PEPDR105

Low molecular weight polyethylene powder for pigment dispersion, mold release.

options

From $8.50 /lb

PVOH4988

High-viscosity, partially hydrolyzed polyvinyl alcohol for diverse applications.

options

From $14.77 /lb

PVOH3099

Medium-viscosity, fully hydrolyzed polyvinyl alcohol with excellent film properties.

options

From $11.23 /lb

PVOH688

Low-viscosity polyvinyl alcohol for textile stiffening and paper sizing.

options

From $11.36 /lb

PVOH6299

High-viscosity, fully hydrolyzed polyvinyl alcohol with excellent tensile strength.

options

From $15.45 /lb

AGERITE® SUPERLITE® SOLID PWD

Antioxidant blend for polymers, non-blooming, FDA-listed, non-staining.

AK100 Silicone Fluid, 100 Cst.

Versatile, high-performance silicone oil for industrial lubrication and release.

AK1000 Silicone Fluid, 1000 Cst.

Linear, non-reactive polydimethylsiloxane with ~1000 mm²/s viscosity.

AK350 Silicone Fluid, 350 Cst.

Non-reactive polydimethylsiloxane with ~350 mm²/s viscosity.

Calcium Carbonate, Fine Ground Limestone, Fcc

Calcium Carbonate, Fine Ground Limestone

Cation Exchange Resin - Strongly Acidic 900 Grams

Water softener resin - 900g strongly acidic.

Cation Exchange Resin 900 Grams

Acidic resin for cation exchange, 900 grams.

Crushed Pine Rosin (For Baseball Rosin Bag and Aquatint Dusting)

Fine crushed pine rosin for baseball and aquatint applications.

Dammar Gum Resin Crystals

White-yellowish, varied grades, natural resin.

Dibutyl Phthalate (DBP)

Plasticizer for plastics, elastomers, coatings, and industrial uses.

Ester Gum (Glycerol Ester of Gum Rosin)

Transparent yellow resin for adhesives, paints, and emulsifiers.

Fumaric Resin

High-performance polymer for coatings and composites.

Gum Arabic, Natural

Natural stabilizer and thickener used in food, printing, paint production, and more.

Gum Rosin Flakes, Brazilian, WW Grade

Light yellow-amber rosin flakes from Pinus Elliottii for versatile uses.

Gum Rosin Lumps, Honduran, Grade WG/WW

High-grade pine rosin with excellent anticrystalline properties.

Hydroxyethyl Cellulose, HEC 250, Natrosol™ 250

thickener for water based products

Liquid Starch 1 Oz

Craft and science experiment starch concentrate.

Magnesium Carbonate, Basic, USP, "Extra Light"

Extra light magnesium carbonate, USP/FCC grade, food/pharmaceutical use.

Microcrystalline Cellulose 101 Nf (Super Fine)

Purified cellulose excipient for direct compression and granulation.

Microcrystalline Cellulose 102 Nf (Fine)

Purified cellulose excipient for pharmaceutical binding and filling.

Partially Hydrogenated Gum Rosin

Adhesive enhancer with improved stability and lighter color.

Polyethylene Powder

Low molecular weight polyethylene powder for pigment dispersion, mold release.

Polyoxyethylene Nonylphenol (Np-9)

Effective nonionic surfactant, widely used, combustible, nontoxic.

Polyvinyl alcohol Grade 22-88, Pva 217, Elvanol 52-22

Water-soluble polymer with excellent film and binding properties.

Polyvinyl alcohol Grade 25-88

Medium-viscosity, partially hydrolyzed polyvinyl alcohol for coatings and films.

Polyvinyl alcohol Grade 49-88

High-viscosity, partially hydrolyzed polyvinyl alcohol for diverse applications.

Polyvinyl Alcohol PVOH3099

Medium-viscosity, fully hydrolyzed polyvinyl alcohol with excellent film properties.

Portuguese Rosin, Flakes,

Rare Brazilian rosin flakes packaged in Portugal.

Rosin Powder Blend With Calcium Carbonate

Fine powder with 80% rosin, 20% calcium carbonate.

Rosin Powder Silica Blend

Custom blend of fumed silica and micronized rosin powder

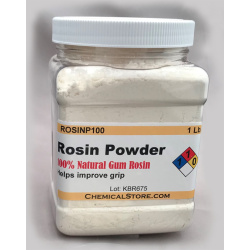

Rosin Powder, 100% Natural Rosin

100% pure powdered Brazilian gum rosin for grip enhancement.

SELVOL 205 Polyvinyl Alcohol, PVOH688

Low-viscosity polyvinyl alcohol for textile stiffening and paper sizing.

Selvol165 Polyvinyl Alcohol Grade 6299

High-viscosity, fully hydrolyzed polyvinyl alcohol with excellent tensile strength.

Sodium Lauryl Sulfate 30%

Highly effective emulsifying cleaning agent for removing oily stains and residues.

Water Soluble Starch, Laundry Starch Powder

Water-soluble laundry and craft starch powder.

- 1

Pigments & Dyes

Pigments & Dyes Metals

Metals Aluminum - Powder

Aluminum - Powder Bronze - Powders

Bronze - Powders Copper - Powders

Copper - Powders Iron Metal - Powders

Iron Metal - Powders Magnesium

Magnesium Metal Electrodes

Metal Electrodes Tin Metal - Powders

Tin Metal - Powders Zinc Metal - Powders

Zinc Metal - Powders Lab Supplies

Lab Supplies Clamps and Supports

Clamps and Supports Glassware

Glassware Handling

Handling Magnifiers

Magnifiers pH Indicators

pH Indicators Plasticware

Plasticware Rubber Stoppers

Rubber Stoppers Rubber tubing

Rubber tubing Steelware

Steelware Test Tubes

Test Tubes Tools

Tools Caliper

Caliper Counter

Counter Hygrometer

Hygrometer Scales

Scales Thermometers

Thermometers Electricity

Electricity Electrodes

Electrodes Multimeters

Multimeters Wires

Wires